TOLERANCING AND ENGINEERING STANDARDSTolerancing is just like written languages. It has its own standards.

There areto many standards like ANSI(Inch System), ISO (Metric System) etc. List of standards: ANSI B4.1, ANSI B4.2, ISO 286, ISO 1829, ISO 2768, EN 20286, JIS B 0401. In an assembly process the degree of 'clearance' or 'tightness' desired between mating parts is important.In a manufacture of a machine, quality is a primary consideration. Manufacturing precision taken into the product determines its quality, its cost and selling price.Parts of a machine are designed in order to make a function. The working parts have a definite relationship with each other: free rotation, free longitudinal movement, clamping action, and permanent fixed position.Precision is the degree of accuracy necessary to ensure the functioning of a part as intended.

Tolerance is the allowable variation for any given size in order to achieve a proper function. Tolerancing DefinitionsNOMINAL SIZE: The size used for general description. Example; 7/8 inch Shaft, 25mm Shaft etc.BASIC SIZE: The size used when the nominal size is converted to the decimal and from which deviation are made to produce limitdimension.Example:.8750inch shaft which is the basic size for a 7/8 inch nominal shaft.25mm nominal size which can be basic size of 24.950mm.LIMIT DIMENSION: The Lower and Upper permitted sizes for a single featuredimension.

Hole Tolerance Calculator

0.500-0.506 inch where 0.500 inch is the lower limit and 0.506 inchupper limit dimensionsTOLERANCE:Tolerance is the allowable variation for any given size in order to achieve a proper function. Tolerance equals the difference between lower and upper limitdimensions.Example; for 0.500-0.506 inch the tolerance would be 0.006 inch.BILATERAL TOLERANCE: It is a way to express tolerance by using both minus and plus variations from a given size. Example; inch. The limitdimensions are1.120-1.130 inch.

The tolerance is 0.010 inch.UNILATERAL TOLERANCE: It is a way to express tolerance byusing only minus or plus variation from a given size. As you can see the first case uses a minus variation.orinch. The first case uses a minus and plus variation.FIT: The general term of fit to describe the range of tightness designed into parts which assemble one intoanother.

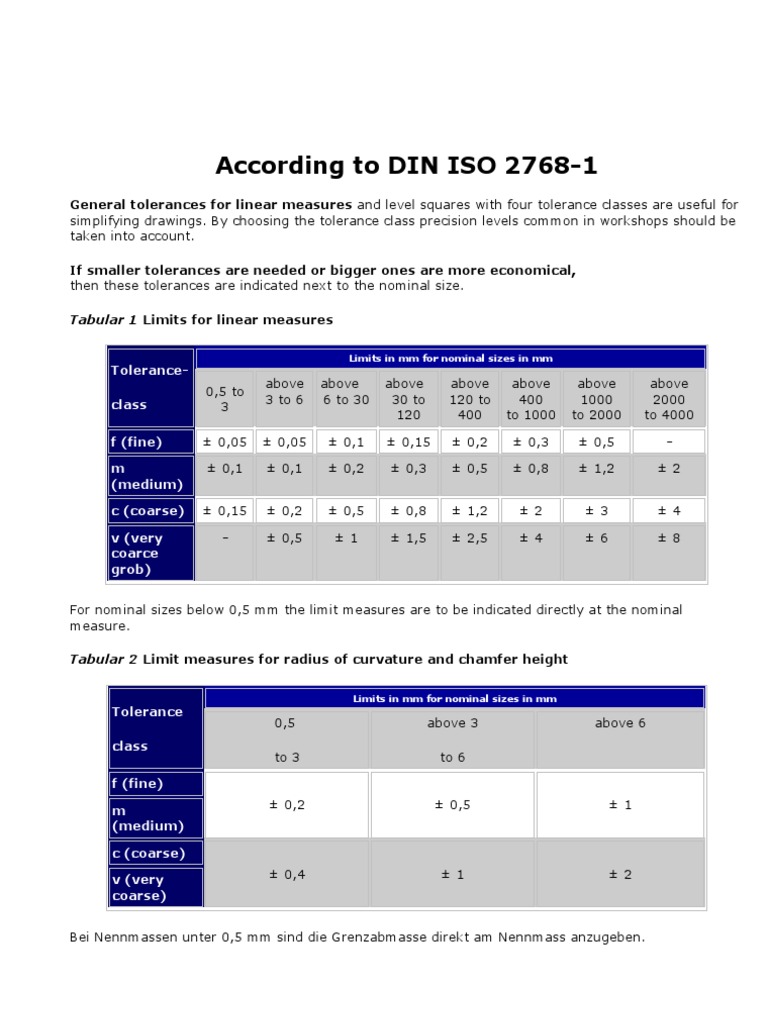

General Tolerances Iso 2768 Mk

The fit can be explained under the three categories.A-CLEARANCE FIT: A type of fit in which one part fits easily into another with a resulting clearance gap.See the below example. An Force (interference) fit. When the shaft is always larger in diameter thanthe hole parts must be assembled by pressure or heat expansion.Tolerance on shaft: 0.001Tolerance on hole: 0.001minimum clearance: 0.500 - 0.503= -0.003 in (the tightest fit 0.003 in interference)maximum clearance: 0.501 - 0.502 = -0.001 in (the loosest fit 0.001 in interference)Maximum clearance=Minimum interferenceMinimum clearance=Maximum interferenceC-TRANSITION FIT: A type of fit in which loosest case provides a clearance fit and the tightest case gives an interference fit. See the example below.